Discover Top Techniques for Effective Auto Tool Cluster Fixing and Maintenance

In the realm of vehicle upkeep, the detailed system of a tool cluster plays a vital duty in providing drivers with essential info regarding their automobile's efficiency. Remain tuned to uncover the top methods that can simplify the procedure of automobile instrument cluster repair work and maintenance, ultimately enhancing your driving experience and vehicle performance.

Usual Instrument Cluster Issues

Some typical issues might occur with car instrument collections, affecting their functionality and precision. This problem can be triggered by a defective fuel degree sensing unit or a defective gauge cluster. These issues can impede the motorist's ability to monitor necessary vehicle information, highlighting the value of prompt instrument cluster repair and upkeep to guarantee ideal functionality and accuracy while driving. tahoe instrument cluster repair.

Essential Tools for Repair

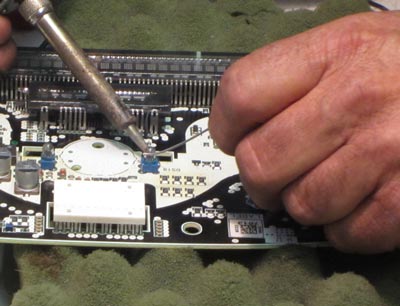

When attending to usual instrument collection concerns such as malfunctioning speedometers, unresponsive gas assesses, or dark dashboard lights, having the essential devices for repair is critical in guaranteeing exact and efficient diagnostics and maintenance. Amongst the key tools needed for auto tool cluster repair work are an electronic multimeter for testing voltage and resistance degrees, a soldering iron for dealing with defective parts or loosened links, and a set of screwdrivers for disassembling the cluster. In addition, specialized tools like collection elimination hooks may be required for securely removing the collection from the dashboard.

Analysis Methods for Troubleshooting

Using sophisticated analysis techniques is essential in successfully fixing problems within auto tool clusters to identify and address underlying troubles accurately. By adhering to systematic diagnostic procedures and analyzing diagnostic results properly, service technicians can enhance the troubleshooting process and make sure the proper functioning of the tool cluster. A thorough diagnostic strategy not only saves time however also advertises accuracy in identifying and solving tool cluster problems promptly.

Cleaning and Maintenance Tips

Software Program Updates and Calibration

Calibration is an additional essential element of preserving your auto instrument collection. This procedure entails readjusting the settings and parameters within the software to make sure that the displayed information, such as speed, gas degree, and temperature, is trusted and accurate. Correct calibration not only boosts the individual experience but additionally adds to safety and security when traveling by offering drivers with precise and trustworthy information.

To make certain that your vehicle instrument cluster functions optimally, it is recommended to adhere to the supplier's standards concerning software application updates and calibration intervals. By remaining aggressive in these locations, you can my company take full advantage of the efficiency and lifespan of your instrument collection.

Conclusion

To conclude, reliable auto tool cluster repair service and maintenance require a comprehensive understanding of typical issues, crucial tools, diagnostic techniques, cleaning up techniques, and software application updates. By using these methods, service technicians can properly repair and solve instrument collection problems, ensuring accurate and trusted efficiency of the car's dashboard display screen. Regular maintenance and calibration are vital to avoiding future concerns and ensuring the proper functioning of the instrument cluster.

When attending to usual tool collection issues such as malfunctioning speedometers, unresponsive fuel evaluates, or dark dashboard lights, having the important devices for repair service is important in making certain precise and efficient diagnostics and upkeep. Among the main tools needed for automobile tool collection repair service are a digital multimeter for screening voltage and resistance levels, a soldering iron for repairing damaged elements dig this or loosened connections, and a collection of screwdrivers for dismantling the collection. In addition, specialized tools like check that collection elimination hooks might be required for safely separating the collection from the control panel.

In final thought, efficient automobile instrument collection repair service and upkeep need a detailed understanding of usual problems, important devices, analysis techniques, cleaning up methods, and software application updates. Normal upkeep and calibration are key to avoiding future issues and making sure the correct performance of the tool collection.

Comments on “Efficient Tahoe Instrument Cluster Repair Solutions: Taking Care Of Gauge Accuracy”